KONAL

Oil Derivatives at the Tank Truck Load-out System

VALLTERA-Tech together with our partners from DieMMe Gmbh is offering DieMMe Gmbh overall OIl Derivatives at the Tank Truck Load-out System "Konal".

The "Konal" is a computer system relying on ancillary industrial equipment and a SCADA control system to provide complete management of the tank truck load-out filling station. The system encompasses activities from the signing of the contract and the drafting of daily delivery plans, identifies and registers the tank-truck company, sets up a filling cue, regulates the access to the filling point, automatically fills the tank-truck and controls the supply of oil derivative, monitors the exit of the tank-truck from the filling point, issues the appropriate documents and registers all the phases in the delivery of oil derivatives. The system also provides remote control and supervision of the filling procedure.

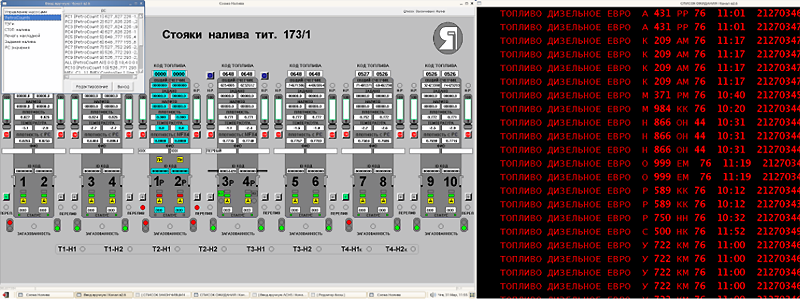

KONAL 2.0 is currently installed and operating at Yaroslavl Oil Refinery, Russia

Functionalities of the KONAL system:

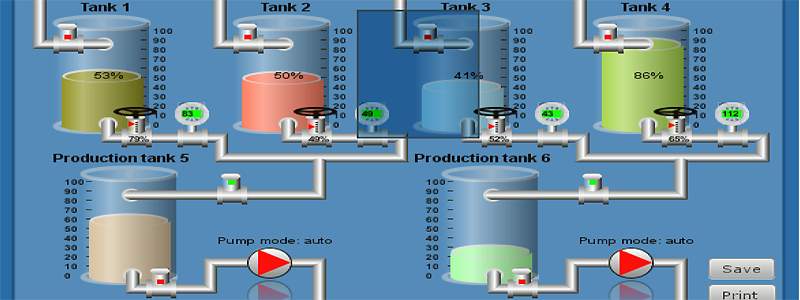

- A SCADA system allows the supervision and administration of fuel transfer from reservoirs

- Supervision and administration of the tank-truck filling process

- The system for the identification and registration of the transport company and the administration of the filling procedure at the platform

- It is directly linked to the accounting and sales departments

- It issues bills of lading

- Chronological registration of all events in the filling system

Loading monitor subsystem

System benefits:

- Prevention of manipulation errors in pouring of oil derivatives in tank tucks

- A more efficient system for the authentication of the user and a quicker release of appropriate documentation. Elimination of human-factor mistakes

- Drastic reduction of personnel needed to run the filling facility

- No exposure of personnel to harsh working conditions and oil derivatives' fumes

- Constant availability of status reports for the filling facility allows timely repair of malfunctions and reduces operation losses to a minimum

- Chronological supervision of the filling facility operation allows a rapid detection of the causes for break-downs and other malfunctions of the system

- Automatic administration of the oil derivatives input allows an even usage of pumps and their minimal idle operation

- The supervision of the processing equipment offers a review of its wear, whilst comparison with the manufacturer's documentation and exploitation characteristics allows a rational and efficient planing of overhauls

SCADA subsystem